Home » Products » Process Engineering - Wastewater Treatment System Equipment » Helixor Diffuser

Helixor Diffuser for Wastewater Treatment Systems

Optimize Your Wastewater Treatment Efficiency with the Helixor Diffuser

Key Features and Benefits

- High Oxygen Transfer Efficiency: The Helixor Diffuser is engineered to maximize oxygen transfer rates, ensuring effective aeration and enhanced biological treatment processes.

- Durable and Low Maintenance: Manufactured using high-quality, corrosion-resistant materials, the Helixor Diffuser provides long-lasting performance with minimal maintenance requirements.

- Energy Efficient Design: The advanced design reduces power consumption, lowering operational costs for wastewater treatment facilities.

- Adaptability and Customization: Available in various sizes and configurations, the Helixor Diffuser can be customized to meet the specific needs of different wastewater treatment systems.

Application of the Helixor Diffuser

- Municipal Wastewater Treatment: The Helixor Diffuser is ideal for municipal wastewater treatment plants, improving the aeration process and ensuring compliance with environmental regulations.

- Industrial Wastewater Treatment: Industrial facilities can benefit from the Helixor Diffuser by improving treatment efficiency and reducing operating costs, particularly in industries such as food processing, chemicals, and pharmaceuticals.

How The Helixor Diffuser Works

The Helixor Diffuser works by introducing fine air bubbles into the wastewater, significantly increasing the surface area for oxygen transfer. This process enhances the aerobic digestion of organic matter, promoting the breakdown of contaminants and improving overall water quality.

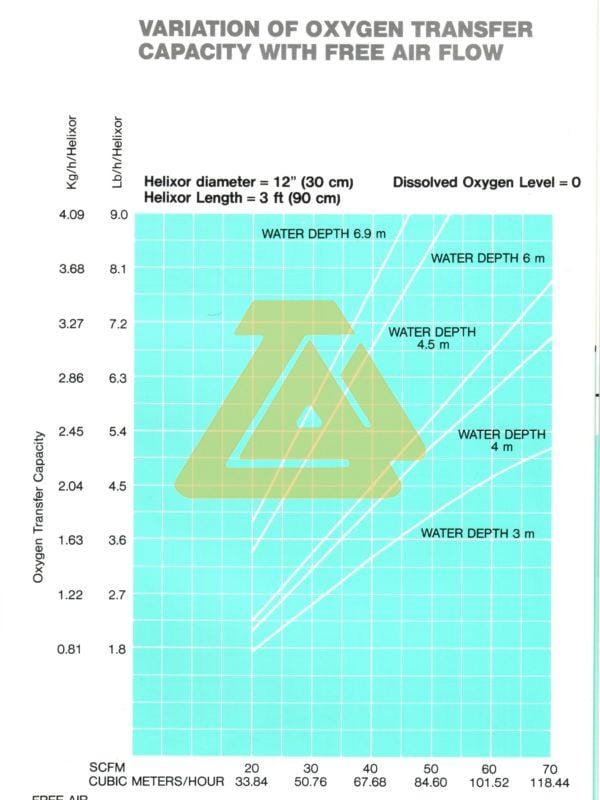

Oxygen Transfer Capacity - 0.90 m Helixor

The Helixor Coarse Bubble Diffusers are installed on the concrete floor of the basin and are submerged in the water. They have no moving mechanical parts, making them simple and reliable.

The Helixor consists of a 12-inch polypropylene (PP) tube made up of several components, including a central helix (spiral) element that divides the tube into two sections.

At the bottom of the tube, compressed air is introduced through two small openings, one on each side of the helix. As the air rises inside the tube, it creates small bubbles and forces the water to flow.

The water and air move through a winding spiral path, which increases the contact time between the bubbles and the water. This turbulence ensures that maximum oxygen is transferred into the water.

Most of the oxygen transfer happens within the Helixor, but as the air and water leave the tube, they form a strong upward jet. This movement pulls more water along and brings additional oxygen to the water surface as the bubbles rise.

Further oxygen transfer occurs as the water spreads outward from the jet, helping oxygenate the surrounding water.

Helixor : Materials and Product Data Sheet

Our Helixor Coarse Bubble Diffuser is made from high-quality, durable materials to ensure reliable performance.

The materials used in the Helixor Coarse Bubble Air Diffuser include:

- Brackets: Made from stainless steel (SS AISI)

- Packing: Made from high-density polypropylene (HDPP)

You will find the product data sheet for the Helixor coarse bubble diffusers we design, manufacture, and supply, along with their key technical properties.