Between the Various Applications , the following are reported :

- Bio-Percolator

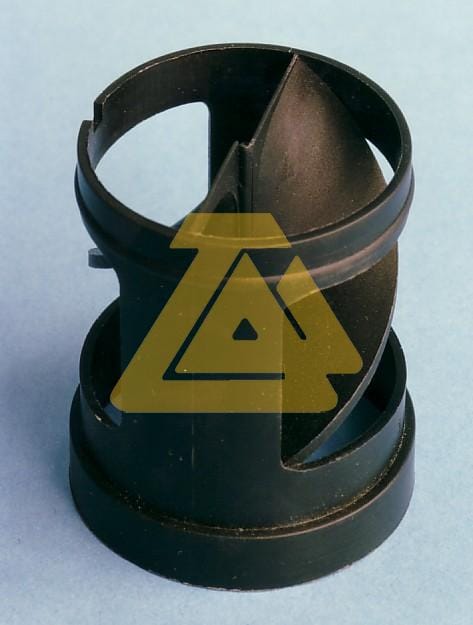

- Absorption Columns

- Washing Towers

- Distillation Columns and Towers

- Exchange Beds

- Washing Tower

- Percolator

- Desorption Columns

- Cooling Towers

- Stripping

- Washing

- Stripping Columns

These applications are used in various industrial sectors, including oil and gas, chemical, petrochemical, oil industries, energy plants, co-generation, water treatment, sludge treatment, and general process engineering.