Advanced Metallurgy

Wilfley’s MAXALLOY® 5A hard iron combines unsurpassed hardness with superior toughness to create the ideal material for high wear applications

MAXALLOY® 5A hard iron is Wilfley’s proprietary version of standard 27% Chrome (ASTM A532 Class III, Type A) that has been specially processed to achieve a much higher hardness (740 HBN). The proprietary processing also increases the pH range, which gives MAXALLOY® 5A a much lower corrosion rate as compared to commonly available high chrome irons.

Chemical Composition

MAXALLOY® 5A vs. Standard 27% Chrome

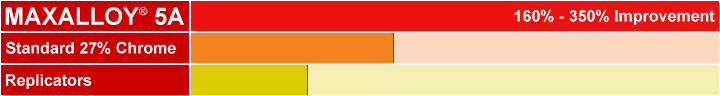

Increased Service Life (Based on test field data)

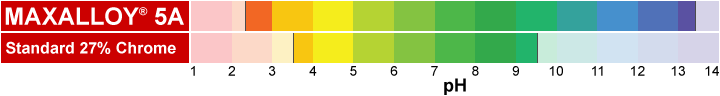

Increased Preferred pH Range (Based on laboratory testing)

Chemical Composition (Weight %)

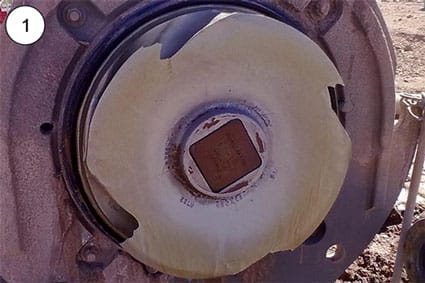

Photo 1 shows a standard hard iron impeller after only 40 service days. Substantial wear can be seen on the impeller edge and vanes.

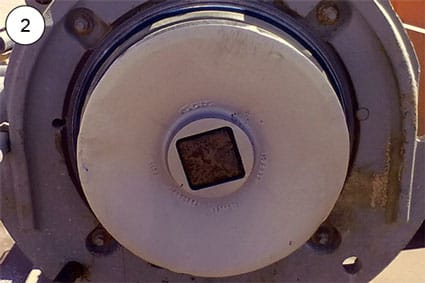

Photo 2 shows a new MAXALLOY® 5A impeller after 97 service days. The pump was reassembled and the impeller ran successfully for 135 service days, over 3 times longer than standard hard iron.

Case Wear in Garnet Mining Application

Photo 3 shows a standard hard iron case after only 5 service days. Deep wear trenches are clearly visible in the case walls because of the lower fracture toughness and hardness. Significant corrosion can also be seen on the exposed surfaces.

Photo 4 shows a new MAXALLOY® 5A case after 21 service days. The wear pattern shows plastic deformation instead of wear trenches, indicating high and uniform hardness distribution through the pump case wall. The MAXALLOY® 5A case also shows no sign of corrosion.